- danish

- english

- afrikaans

- albanian

- amharic

- arabic

- armenian

- assamese

- aymara

- azerbaijani

- bambara

- basque

- belarusian

- bengali

- bhojpuri

- bosnian

- bulgarian

- burmese

- catalan

- cebuano

- corsican

- creole

- croatian

- czech

- deutsch

- dhivehi

- dogrid

- dutch

- estonian

- ewe

- filipino

- finnish

- french

- frisian

- galician

- georgian

- greek

- guarani

- gujarati

- haitian_creole

- hausa

- hawaiian

- hebrew

- hindi

- hungarian

- icelandic

- igbo

- indonesian

- irish

- italian

- japanese

- kannada

- khmer

- kinyarwanda

- korean

- kurdish

- kurdish_sorani

- kyrgyz

- lao

- latin

- latvian

- lithuanian

- luganda

- luxembourgish

- macedonian

- maithili

- malay

- malayalam

- maltese

- maori

- marathi

- nepali

- norwegian

- nyanja

- oromo

- pashto

- persian

- polish

- portuguese

- punjabi

- quechua

- romanian

- russian

- samoan

- sanskrit

- scottish_gaelic

- shona

- sindhi

- singapore

- slovak

- slovene

- somali

- spanish

- swahili

- swedish

- tajik

- tamil

- tatar

- telugu

- thai

- turkish

- turkmen

- twi

- ukrainian

- urdu

- vietnamese

- welsh

- yiddish

- yoruba

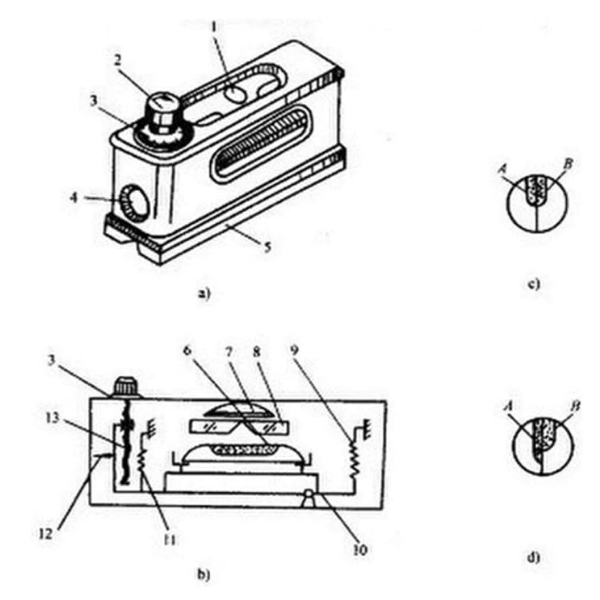

Matakin Hoto na Optical Composite

Bayanin samfurin

- 1.Application

An yi amfani da matakin hoto na gani sosai a auna gradients na lebur farfajiya da kuma yanayin silima ya zama madaidaiciya; Jirgin saman da kuma kai tsaye na slideway ko tushe na inji kayan aiki ko kayan aikin injin din na optical da kuma daidaituwar shigar da kayan aiki.

- 2.tectical data

(1) Kowane darajar karatun: 0.01mm / m

(2) Max Aunawa kewayo: … 0 ~ 10mm / m

(3) Bada izinin: … 1mm / a cikin mita ɗaya … 0.01mm / m

A cikin cikakken kewayon … 0.02mm / M

(4) karkacewa a saman farfajiya … 0.0003M / m

(5) Kowane darajar karatun na matakin ruhu … 0.1mm / m

(6) Workomet (LW): … 165 48mm

(7) Net nauyin kayan aikin: … 2kgs.

- RAYUWAR CIKIN SAUKI:

Matakin Hoto na Hoto ɗin galibi ya ƙunshi sassan da ke gaba kamar Micro Daidaita dunƙule, goro, matakin da aka kammala, liyafa mai girma, prism, gilashin ruhu, mai girma ƙasa tare da bayyana.

- 4. Komawa manufa:

Matsayin hoto na Hoto yana amfani da tsararraki don samun hotunan iska a matakin matakin Ruhu da ke haɓaka tsarin karatun da yake haɓaka tsarin karatun. Saboda haka idan kayan aiki tare da gradient na 0.01mm / M, ana iya karanta daidai a matakin hoto na hade (matakin ruhu a cikin matakin hoto na wannan yana taka rawar da ke nuna alamar sifili).

- Har yanzu:

Sanya matakin hoto na Hoto akan saman aikin auna kayan aiki da kuma gradient na ma’aunin kayan aikin da ke haifar da uncoindi na hotunan tashar iska; Juya karatun digiri na digiri har zuwa pow na iska kumfa akwai daidai da karatun zai iya kai tsaye. Ainihin gradi na auna kayan aikin za a iya lissafin ta hanyar tsari mai zuwa:

Ainihin gradient = mafi girman darajar Daraja Daraja Karshe

Misali Misali: Dokar Karanta: 5 gradients; Kamar yadda wannan matakin hoto na haɗin an saƙa shi da darajar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta, wannan shine darajar gradient: 0.01mm / M da Fulltrum Distance: 165mm.

Don haka: ainihin gradient = 165mm 5 0.01 / 1000 = 0.00825mm

- Karatun sanarwa:

(1) Kafin amfani, tsaftace ƙashin man mai tare da fetur sannan mai tsabta tare da gauze mai narkewa.

(2) Canjin zazzabi yana da babban tasiri akan kayan aiki sabili da haka dole ne a raba shi da tushen zafi don nisantar da kuskure.

(3) A lokacin aunawa, jujjuya bayanan da aka sazanta har zuwa manyan hotunan iska mai ƙarfi gaba daya ya halarta sannan kuma za’a iya yin karatu a duka tabbatacce da tabbatacce.

(4) Idan an samo kayan aikin tare da daidaitaccen yanayi, ana iya gyara shi; Sanya kayan aiki a kan tebur mai tsayayye kuma juya wanda aka sauya bayanan da za’a iya saita hotunan Tow Air Bubble ya zo; Sa’an nan kuma kunna kayan aiki da 180o kuma ku mayar da shi asalin wurinta. Raby juyawa da aka sazara don samun kumburin iska a iska mai ƙarfi ya zo daidai don samun karatun na biyu b. Don haka 1/2 (α + β) shine karkatar da sifilin kayan aikin. Sassauta da aka tallafa wa sukurorin tallafi uku a kan Discated Disc kuma latsa ɗauka da sauƙi ta hannun embossed Daidaitawa hula; Juya diski ta 1/2 (α + β) don samun karkatar da sifili da kuma haɗin layin; A ƙarshe ɗaure skrus.

(5) Bayan aiki, dole ne a tsabtace kayan aiki da kuma mai rufi tare da acid kyauta, anhydrous, mai maganin sihiri. Sanya shi cikin akwatin katako sannan adana shi a cikin wuri mai tsabta.

Sch

Samfurin samfurin

Sigogi na fasaha

- Farantin lamba kira 0.01 mm / m

- Kewayon rubutu 0-10 millimeters / mita

- Kuskuren yara-yaro a cikin ± 1mm / m + 0.01 mm / m

- Kuskuren iyaye a cikin kewayon kowane yanki shine ± 0 02 millimita / mita

- Bench shimfiɗa karkatar da 0.003mm

- Cell darajar darajar 0.1 millimita / mita

- Girman Deliep na Ofishin 165 x 48 millimita

- Net nauyi na 2.2 kilogram

Entical Hoton Hoton Hoton Hoto: Antirust Man & Stage Nasihu

Matsakaicin da ya dace yana tabbatar da matakin hoto na ganima na gani wanda yake riƙe da shi 0.01mmm / m daidai da karko. Bi waɗannan matakan don kare fasahar ta da na inji:

1. Tsabtace kullun don kariya ta ƙasa

Bayan amfani, shafa matattara mai aiki (V-Groove, gefuna, ruwan tabarau) tare da kayan maye akan kaya a kan lint-kyauta don cire mai da ƙura. Yi amfani da buroshi mai laushi don markon mai taurin kai – Abincin Absasives, wanda zai iya daskarewa na gani sassan ko lalata sutturar ƙarfe. Wannan yana kiyaye madaidaicin ƙasa (Ra ≤ 0.1μm) m don ingantaccen karatu.

2

Duk da yake Granite gindi ya tsayayya da lalata, kayan ƙarfe (sukurori, levers) suna buƙatar kariya. Aiwatar da maganin ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta mara ƙarfi a kowane watanni 3 ko bayan bayyanar danshi:

Aiwatar da thinly zuwa zaren da kuma pivots tare da digo, guje wa tafki a kan granit / ruwan tabarau.

Yana hana kayatarwa: kula da abin da zai haifar da na Lever (0.001mm daidai) don ma’aunin sililin silili.

3. Kyakkyawan kayan ajiya

Adana a cikin yanayin wahalar ko kuma auren ƙasa don guje wa zazzabi / zafi:

Yanayi: 10 ° C-30 ° C, <60% zafi don hana ruwan tabarau da murdiya.

Sanya: sa lebur ko madaidaiciya a cikin kwandon shara; Karka taɓa ƙarƙashin abubuwa masu nauyi don guje wa ba daidai ba tsarin tsarin gani.

Adana na dogon lokaci: mai yiwuwa mai-tsatsa mai kuma ƙara silica fakiti; Bincika awanni 24 kafin amfani, tabbatar da matsayin sifili ta 180 ° juyawa sau goma.

4. Binciken Ayyukan Wata

Duba aiki akai-akai don tabbatar da amincin:

Bubbles formality: Tabbatar da hoton kumfa mai kyau daidai ba tare da blur ba.

Lever motsi: gwada micro-skurs don m jujjuyawar alama da ake buƙata lubrication.

Binciken Fire: Yi amfani da farantin tunani don inganta fare na masana’antu (± 0.000.stm / m).

5. Tallafin Storaen na tsawon rai

Leverage kwararrun ayyukanmu don kula da yawan aikinmu:

Mai tattara kudi na masana’antu: Maido da 0.01mm / m daidaita ta kayan aiki na Iso-ba da izini ga mahimmancin aikace-aikace.

Abubuwan da ke da gaske: Abubuwan haɗin Sauya suna tabbatar da daidaituwa da kiyaye ainihin daidaito.

Ta bin waɗannan matakan, matakin ƙirar hotonku na Haske zai Iya isar da daidaitaccen daidaito na masana’antu, wanda aka tallata ta ƙwarewarmu na 30+.

Matsayin sifili sau da yawa na Hoton Hoto na Optical: 180 ° hanyar juyawa da aka bayyana

Cikakken Calittarancin Sauƙi kaɗan yana da mahimmanci don matakin hoto na Hoto na Storaen don kula da shi na 0.01mm / m daidai da ± 0.0003m / m flawn. Hanyoyin juyawa na 180 na 120 yana kawar da daidaitattun abubuwa masu dabara ko na injin, don tabbatar da matakan dogara cikin mahimman ayyukan CNC kamar jeri na CNC. Anan ne Mai Runduna, Jagorar Mataki:

1. Me ya sa ke ɗaukar?

Tasri, rawar jiki, ko zazzabi, ko zazzabi na iya canjin matakin sifilin sifilin, jagorar mawuyaci. Calibration nazarin kumatun vial tare da kayan aikin kayan aiki na kayan aiki, da tabbatar da tushe na masana’antu ko tsarin tabbatar da jagororin injin.

2. Bukatun Saiti

Storaen Eptical Hoton Hoto (wanda ke nuna tushe na V-Grooved tushe da micro-daidaita dunƙule)

Tabbatacce Tabbataccen Tsarin Layi (misali, namu Storaen Granite Plat, tare da shimfiɗa ≤0.0002mm / m)

Aiki mai tsabta, rawar jiki kyauta-kyauta a cikin yanayin zafin jiki mai tsafta (18 ° C-22 ° shawarar)

3. Mataki na 1: ma’aunin farko

Sanya matakin tsawon lokacin da aka yi magana a cikin gida, a daidaita tushen v-tsagi tare da filin tsakiyar lebur. Juya da dunƙulen micro-daidaita dunƙule har sai da hoton kumfa mai dauke da shi-tsarin 45 ° prism-prism-tsarin-daidai ya mamaye shi a cikin mai duba. Yi rikodin wannan karatun na farko (a), wanda ke nuna karkara daga yanayin yanzu.

4. Mataki na 2: 180 ° juyawa & karatun na biyu

A hankali jefa matakin 180 ° ƙarshen-zuwa-ƙare yayin riƙe da layi na tsaye a ɗakin kwana (guji kowane motsi na ƙarshe). Daidaita micro-dunƙule sake don daidaita hoton kumfa da yin rikodin sabon karatun (b). Bambanci Δ = | A – B | yana nuna kuskuren matsayin sifili; Kyakkyawan dabi’u don matakan stora ya kamata ya zama ≤0.005mm / m.

5. Mataki na 3: Gyara kuskure & Tabbatarwa

Lissafta da manufa sifili matsayi kamar tsakiyar: C = (A + B) / 2. Sarar gida mai kariya akan dunƙule-gyara-sifili (yawanci kusa kusa da kumfa, yana juya dunƙule har sai sikelin ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C, sannan ya karanta C. Maimaita matakai 3-4 har sai Δ ≤0.002mm / m, tabbatar da ƙarancin kuskuren ƙasa.

6. Prophi shawarwari na daidai

Daidaitawa sau uku: yi hawan keke na 3, musamman ma bayan jigilar matakin ko aiki a cikin mahalli tare da swings na zazzabi, don tabbatar da sakamako mai sauyawa.

Sa mai motsi sassa: Aiwatar da digo na mai ba na acidic ga micro-acid ga tabbatar da santsi, aiki-baya-baya da hana ɗauri.

Ikon muhalli: Guji kakkan kewaye da tafiye-tafiye na zafi ko drafts, kamar yadda ƙananan ƙananan ƙwayoyin cuta na iya shafar kwanciyar hankali na Granite kuma gabatar da kurakurai.

7. Tallafin Tallafin Storaen

Kowane storaen Eptical Hoto Hoto ya haɗa da takardar shaidar daidaitawa ta nist-gano, amma ana ba da shawarar rajistan ayyukan kwata-kwata don amfani mai nauyi. Tallafinmu ya hada da:

Karatun masana’anta: Maido da ainihin 0.01mmm / m daidaito ta amfani da masu amfani da laser don aikace-aikacen aikace-aikacen kwamfuta don aikace-aikacen manyan abubuwa.

Abubuwan da ke tattare da kayan kwalliya na gaske: ana iya amfani da su na daidaitawa da kuma kayan aikin kiyayewa na dogon lokaci na dogon lokaci.

Koyarwar bidiyo & Jagorar Jagora: Mataki-mataki-mataki na Bidiyo da Tallafi na Injiniya don taimakawa hanyoyin daidaitawa na yanar gizo.

Bayanan karshe

Hanyar jujjuya 180 ° ta tabbatar da matakin hoto na Hoto na EntLoen ɗinku na nuna daidaito da ake buƙata ga ma’aunin sloperical, da sauran hanyoyin da ke cikin ƙasa. Tare da daidaitawa mai kyau, wannan kayan aiki, wannan kayan aikinmu na ƙwarewarmu, ya zama babban rabo na injiniya, tabbatar da kowane gwargwado kamar yadda na farko.

Related PRODUCTS